Implementing an ‘Integrity Operating Window’ Program

Country Websites

Business Websites

We provide engineering - fitness-for-service evaluation (FFS). These assessments are quantitative engineering evaluations, performed to demonstrate the structural integrity of an in-service component. Engineering works in combination with MISTRAS' Mechanical Integrity (MI), Risk-Based Inspections (RBI) and Plant Condition management Software (PCMS). MISTRAS Engineering also performs non-intrusive inspection (NII) analysis, piping integrity evolutions, materials and quality engineering, welding engineering, damage mechanism analysis. We also provide fixed equipment engineering regarding rerates of pressure vessels, fatigue analysis, surface replication and life assessment. Asset Integrity Management Services (AIMS) provides development of MI programs, MI gap analysis, base line thickness surveys, special emphasis programs, visual and NDE inspections, computer-aided design (CAD) inspection drawings, inspection documentation, extraction of inspection drawings from plant 3D model, and generates inspection and test plans.

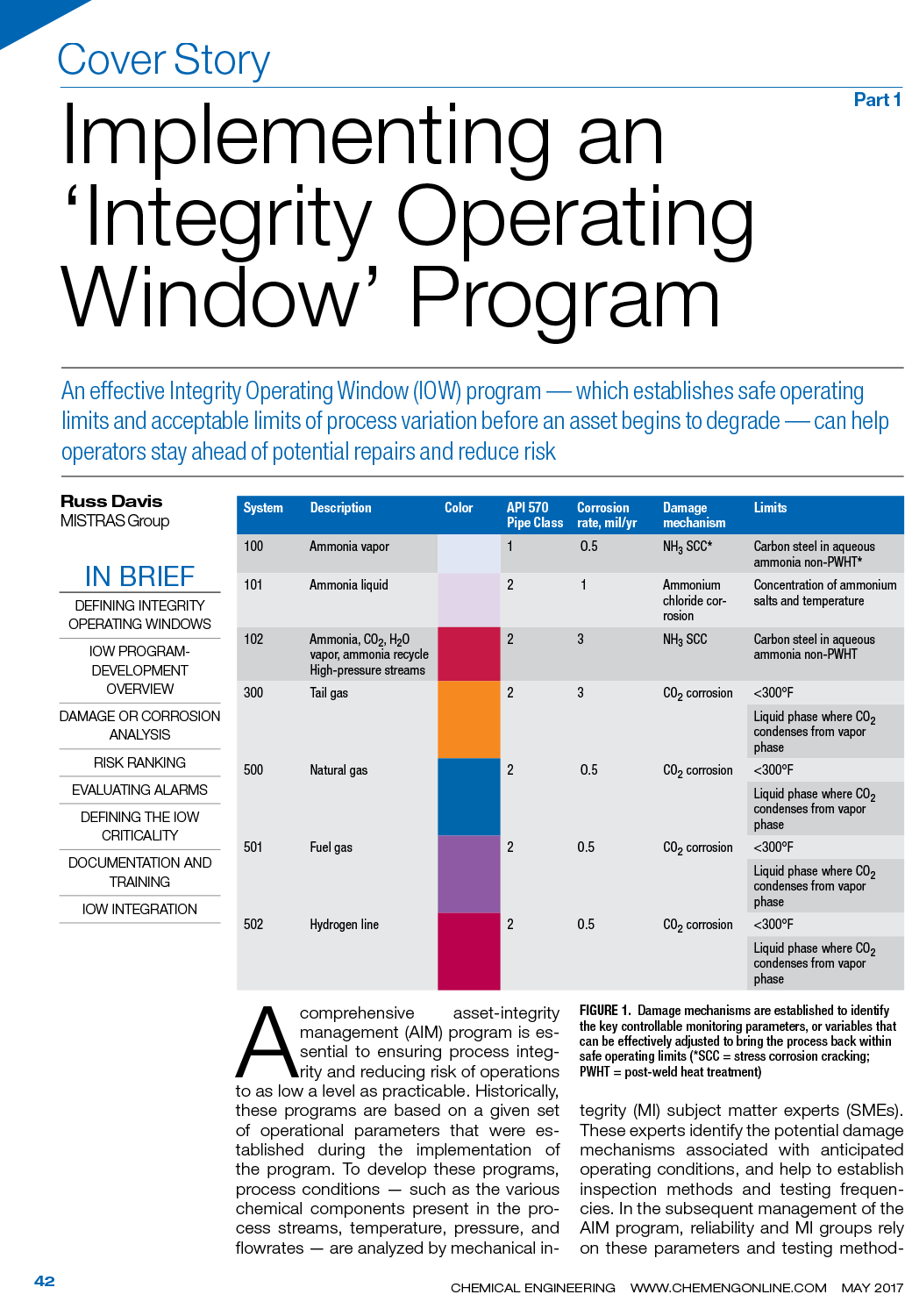

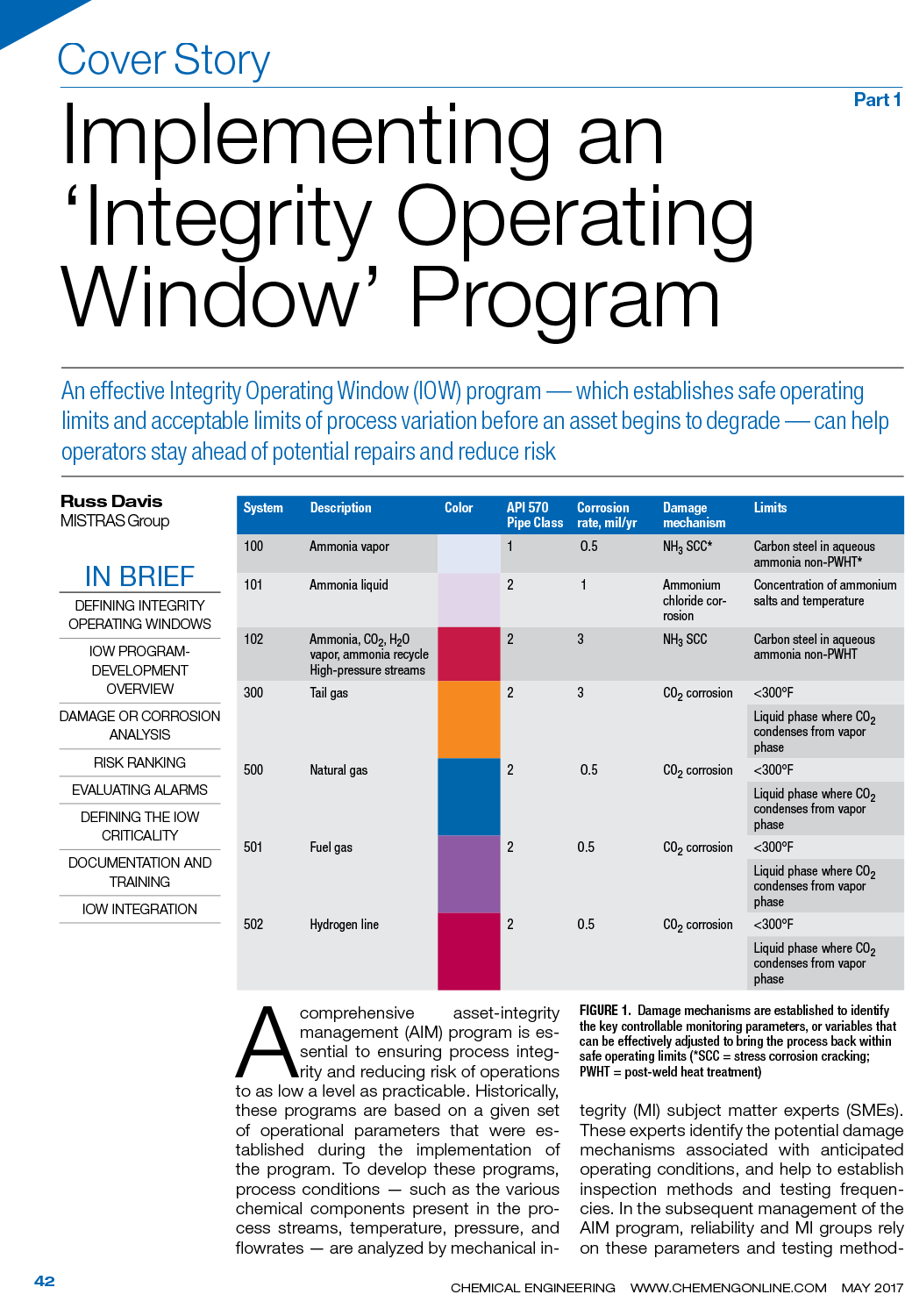

Implementing an ‘Integrity Operating Window’ Program

An article on establishing Integrity Operating Windows (IOWs) as part of a plant-wide mechanical integrity (MI) program initiative.

Non-Intrusive Inspections (NII)

In a story published in Hydrocarbon Engineering magazine, MISTRAS outlines the required steps for developing and executing an effective Non-Intrusive Inspection (NII) program and describes the benefits when compared to traditional inspection techniques.

MISTRAS Engineering Services Brochure

A trifold brochure for Engineering Services, covering our solutions for plant equipment support, profit improvement, and project planning & execution.