world’s

most

vital assets

deep industry

expertise

ahead

In industries where every decision matters, staying ahead means knowing what’s coming — not just reacting when it happens. MISTRAS helps you anticipate risk, improve reliability, and unlock smarter performance through integrated solutions that combine data intelligence, expert inspection, and advanced materials testing.

Schedule expert consultationUniting actionable data, human expertise and precision engineering

DATA Solutions

Information to insight

From software platforms to monitoring technologies, turn raw asset data into actionable insights.

ExploreFIELD Services

Compliance to confidence

Inspect and test your assets to ensure they are operating efficiently, and detect damages before they lead to potentially more dangerous consequences.

ExploreIN-LAB Services

Precision to resilience

With advanced technology, expertise and end-to-end solutions, we help you gain complete control and confidence across your supply chain.

ExploreInnovation to keep tomorrow on track

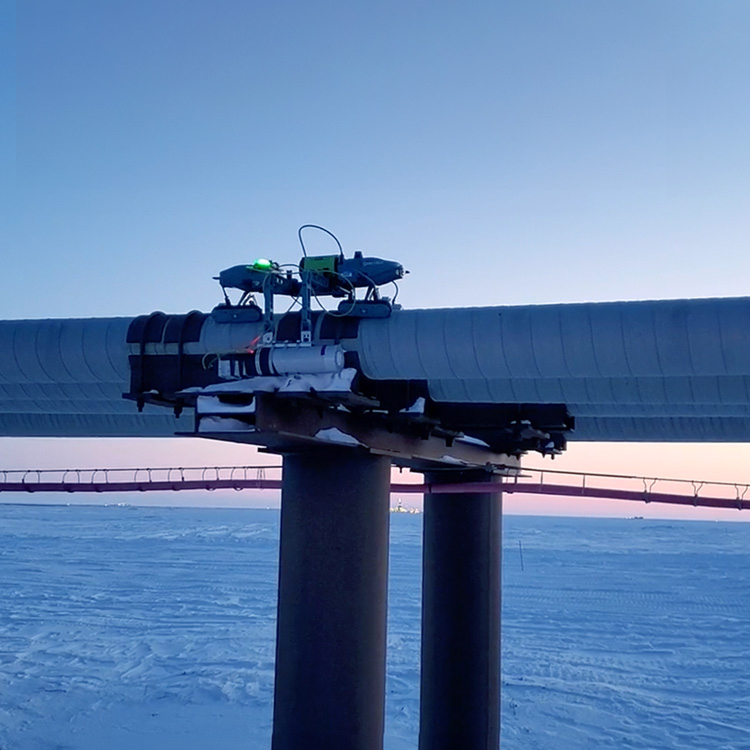

MISTRAS’ ART Crawler services utilize digital radiography (DR) to inspect for internal corrosion and CUI in your insulated and uninsulated aboveground piping and pipeline assets.

Learn more

MISTRAS’s LSI robotic scanning services automate efficient inspections for corrosion and erosion on large assets, dramatically cutting time and cost compared to traditional NDT.

Learn more

MISTRAS's Spider SA scanning delivers flexible, precise NDT for rapid quality assessment of large components like wind rotor blades without damage.

Learn more

MISTRAS Group’s TriStream MFL Ultra-High Resolution ILI is a game-changing, advanced inspection technology that uses multiple magnetic vectors, caliper, and IMU to deliver unparalleled detail on metal loss, deformation, and precise positioning for superior pipeline integrity data.

Learn more

MISTRAS’s TankPAC® is an essential Non-Destructive Testing (NDT) tool for the non-intrusive assessment and comprehensive corrosion monitoring of Aboveground Storage Tank (AST) bottoms, eliminating the need for costly shutdown and cleaning.

Learn more

MISTRAS’s MONPAC system is an Acoustic Emission (AE) test that uses high-speed sensors to detect real-time defect development and evaluate the structural integrity of metallic pressure vessels, spheres, and tanks during a single pressure test.

Learn more

Find your solution

Whatever the challenge, we have the depth of expertise and breadth of solutions to deliver certainty.

Protecting our world, one asset at a time

Be a catalyst for progress

Join a team that protects the world’s vital assets by driving innovation, anticipating needs, and being first to provide solutions that empower customers to lead the way.

Explore careersAchieve new levels of intelligence

Partner with MISTRAS to empower your teams to achieve new levels of reliability, safety, and operational performance.

Schedule expert consultation